Innopower Ceramic fiber brush - metal polishing specialized brush

Efficient, durable, and precise metal surface treatment solutions

Product Introduction

As an efficient tool designed specifically for metal polishing, ceramic fiber brushes use ceramic fiber filaments as the core bristles. With unique material advantages and innovative designs, they have become an ideal choice for deburring and precision polishing on CNC and other automation equipment, bringing significant breakthroughs in cost reduction and efficiency improvement to the manufacturing industry.

Product Features

Efficient grinding

Using ceramic fiber bristles, high polishing efficiency, greatly reducing production cycle;

Fine polishing

The bristles are evenly distributed and combined with the brush body design, which can adhere to the metal surface, effectively remove scratches, oxide layers, and burrs, polish the surface of metal workpieces, and reduce roughness;

Durable and cost reducing

Ceramic fiber bristles have a longer service life than ordinary bristles, reducing tool replacement times and overall usage costs;

Global adaptation

Supports complex working conditions such as flat surfaces, grooves, and stepped surfaces. Whether it is stainless steel, aluminum alloy, automotive parts, or hardware accessories, uniform polishing can be achieved.

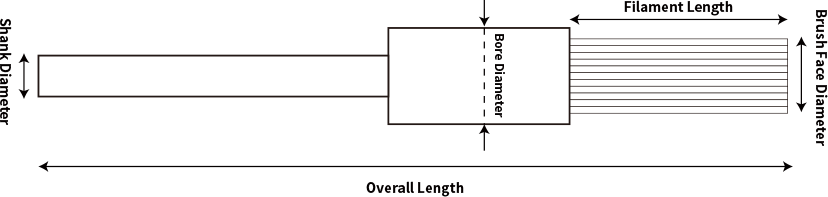

Technical Specifications

| Mesh Size | Brush Face Diameter(mm) | Shank Diameter(mm) | Usage Effect | Applicable Material |

|---|---|---|---|---|

| 60#-3000# | 6-25mm | 4-12mm | Polishing | Stainless steel, aluminum alloy and other metals |

| customizable | customizable | customizable | Cutting mark removal/burrs/polishing | customizable |

Widely used

- Suitable equipment: Suitable for automation equipment such as CNC, composite machine tools, specialized machine tools, robots, etc, and water needs to be added for cooling during use.

- Applicable industries: precision machining industry, 3C industry, automotive industry, and aviation industry.

Precautions for use

- Before use, it is necessary to check whether the brush head has any damage such as loose bristles or cracked brush handle. If there are any abnormalities, they should be replaced immediately to avoid damaging the workpiece or causing safety issues during processing.

- Based on the material hardness, burr size, and precision requirements of the aluminum alloy workpiece, confirm whether the selected ceramic grinding brush matches the mesh size and specifications. It is not recommended to mix unsuitable models.

- Operators are required to wear protective equipment, including dust masks (to prevent inhalation of dust generated during grinding), protective goggles (to avoid splashing debris and eye injuries), and anti slip gloves (to enhance operational stability and prevent hand scratches).

- Operation parameter control: control the machining speed; Maintain even and gentle pressure during operation to avoid excessive pressure; Control processing time.

- Prohibit the use of pneumatic rotating tools.

- After processing, it is necessary to promptly clean the residual dust and aluminum shavings on the surface of the brush head to avoid residual impurities blocking the abrasive gap and affecting the next use effect.

Why choose our polyurethane polishing head?

Shenzhen Innopower New Materials Technology Co.,Ltd. possesses robust R&D capabilities, with a team led by a director with over 20 years of experience in the abrasives industry. The company has independently mastered ceramic fiber brush filaments and polyurethane formulations, continuously refining its products for compatibility across diverse scenarios. The sales team has in-depth market knowledge and provides precise recommendations for deburring grinding heads and ceramic fiber brushes. The experienced after-sales team ensures swift response to guarantee production continuity and offers customized polishing solutions. Upholding the mission of providing efficient and high-quality solutions for the manufacturing industry, choosing LiChuang enables efficient, stable, and cost-effective metal processing. For inquiries: +86 134 3133 4931.