Deeply cultivating technology and focusing on innovation: How does Innopower Ceramic Fiber Brush help reduce costs and increase efficiency in metal polishing

Since its establishment, Shenzhen Innopower New Materials Technology Co.,Ltd. has always regarded technological innovation and product quality as the core driving forces for enterprise development. From the initial 300 square meter laboratory to the modern R&D and production base of over a thousand square meters today, Lichuang has always focused on the research and manufacturing of high-end polishing consumables. Its ceramic fiber brush series products, with excellent performance, are gradually becoming an ideal solution for cost reduction and efficiency improvement in the industrial polishing field.

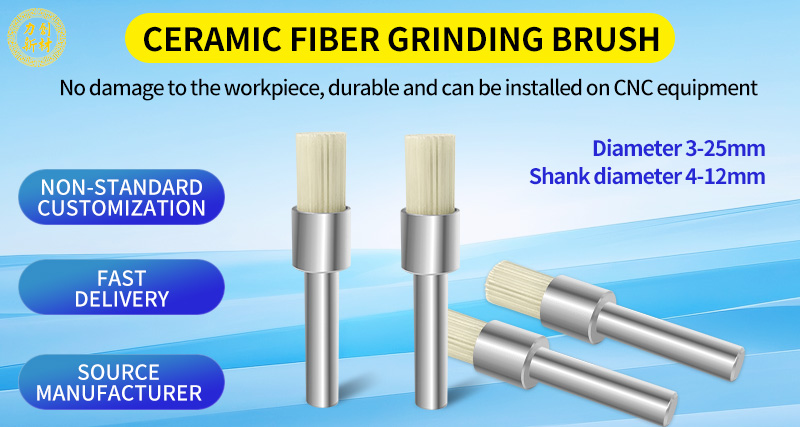

Ceramic fiber brush, as a new type of automated grinding tool, uses special ceramic materials to make bristles, which have five core characteristics: adaptive grinding force, high cutting performance, high temperature resistance, long life, and excellent stability. Its bristles can be flexibly adjusted according to the surface contour of the workpiece, achieving efficient and precise polishing and deburring treatment. At the same time, the continuous self sharpening cutting edge ensures stable polishing ability, significantly improving the efficiency and consistency of automated machining.

In the surface treatment of various metal materials such as hardware, stainless steel, aluminum alloy, copper, etc., Lichuang ceramic fiber brush is widely used to remove burrs, milling marks, oxide layers, improve surface roughness, and achieve mirror effect. This product can be adapted to automation equipment such as CNC machine tools, precision carving machines, robots, etc., greatly reducing manual intervention, shortening processing cycles, and lowering overall production costs.

The company has strong research and development capabilities, with a core team composed of material science PhDs, mechanical engineers, and grinding and abrasive experts with more than 20 years of experience. It is always committed to tackling and improving core technologies such as ceramic fiber bristles and polyurethane composite materials. Through continuous product optimization and innovation, Lichuang not only helps customers achieve significant improvements in polishing efficiency, but also excels in controlling defect rates and reducing overall costs.

Lichuang attaches great importance to customer needs and can provide customized products and technical solutions for various enterprises such as automobile manufacturing, 3C electronics, aerospace, precision machining, etc. Whether it's composite machine tools, specialized lathes, or automated production lines, Lichuang Ceramic Fiber Brushes can efficiently address the surface treatment challenges of complex components, helping end users achieve effective control of polishing costs while providing distributors with more competitive high value-added products.

Lichuang not only provides high-quality polishing products, but also has an experienced sales and after-sales service team that can quickly respond to customer needs, provide professional technical support and on-site services, and ensure worry free production for customers.

Looking ahead to the future, Lichuang will continue to adhere to the concept of "innovation driven, quality-oriented", continuously promote the technological iteration and application expansion of ceramic fiber brushes, and strive to provide more efficient, stable, and environmentally friendly polishing solutions for global manufacturing customers. Welcome to learn more about cooperation details through the consultation hotline 13431334931. Lichuang looks forward to working with you to promote new developments in the polishing field.