Innopower Imitation polyurethane polishing head - metal polishing

Efficient, durable, and precise metal surface treatment solutions

Product Introduction

For mold polishing, precision component polishing, and various surface treatment tasks, suitable polishing tools can make the work more efficient. Customized imitation polyurethane polishing head is such a practical tool, which is made of polyurethane foam material as the basis and contains abrasives inside. It combines elasticity and grinding performance, and can handle polishing operations for various metals.

Product Features

Combining elasticity and wear resistance:

The unique micro porous structure inside endows the product with excellent elasticity and wear resistance, extending its service life while maintaining polishing effect;

Automated and efficient polishing:

specially designed for automation, perfectly adapted to CNC machine tools, five axis polishing machines, precision engraving machines, and robotic arms, achieving stable and efficient batch polishing operations;

Accurate imitation and uniform surface:

The curved surface design of the middle frame ensures uniform overall removal, effectively avoiding wiring problems caused by traditional sponge sand polishing, achieving smooth and natural arc transitions, and improving the consistency of the workpiece surface;

Uniform particle size and stable effect:

Selected abrasives with uniform particle size distribution ensure stable and reliable polishing effect.

Technical Specifications

| Mesh Size | Diameter(mm) | Shank Diameter(mm) | Usage Effect | Applicable Material |

|---|---|---|---|---|

| 60#-5000# | 6-100mm | 4-20mm | polishing | Suitable for metal materials such as aluminum alloy/titanium alloy/stainless steel |

| customizable | customizable | customizable | Cutting mark removal/burrs/polishing | customizable |

Widely used

- Suitable equipment: CNC, five axis polishing machine, precision engraving machine, robotic arm and other automated polishing equipment can be used in conjunction with it, and water needs to be added for cooling during use.

- Applicable industries: precision machining industry, 3C industry, automotive industry, and aviation industry.

Precautions for use

- Before use, please check if the grinding head is securely installed to avoid detachment during high-speed rotation

- Customize suitable grinding heads according to different processing requirements to avoid excessive grinding

- Please wear safety equipment such as protective goggles and gloves during operation to ensure personal safety

- Regularly check the wear of the polishing head and replace severely worn products in a timely manner

- Please clean the residue on the polishing head after use and store it properly in a dry and ventilated place

- Do not exceed the maximum applicable speed of the polishing head to avoid danger

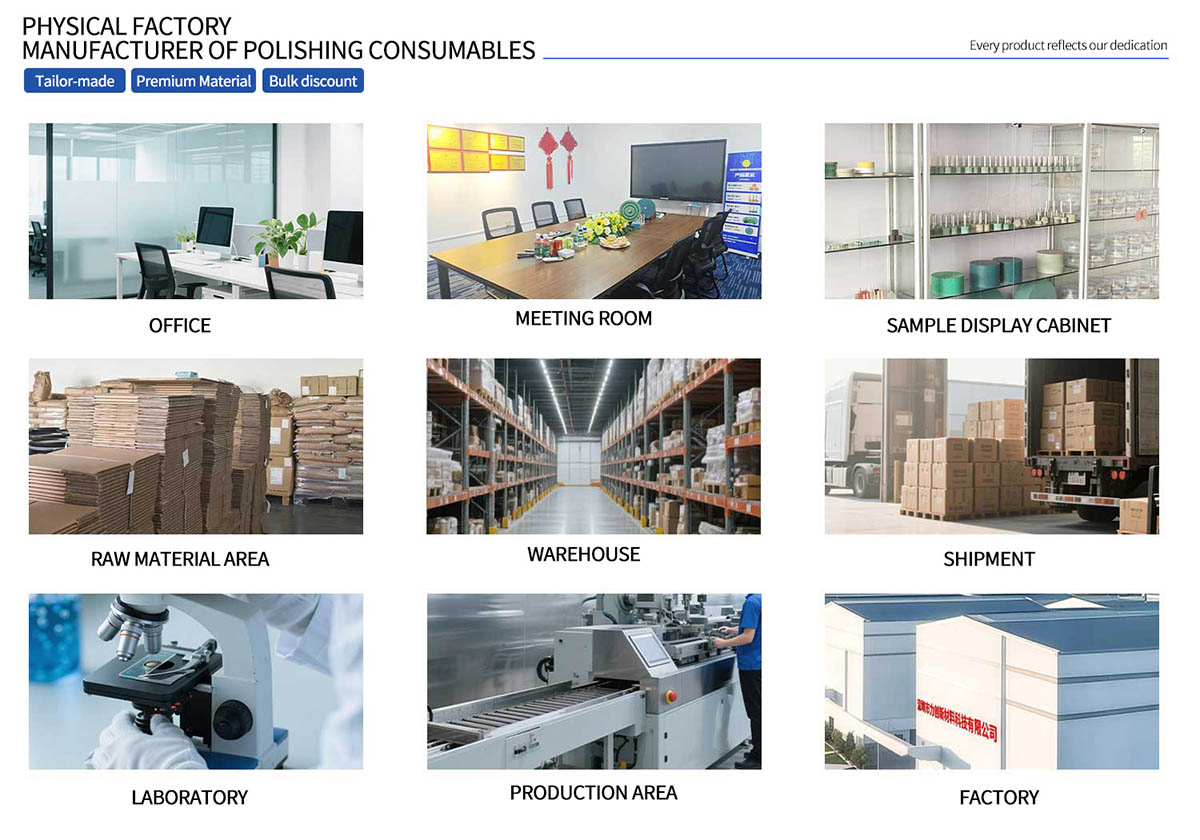

Why choose our polyurethane polishing head?

Shenzhen Innopower New Materials Technology Co.,Ltd. possesses robust R&D capabilities, with a team led by a director with over 20 years of experience in the abrasives industry. The company has independently mastered ceramic fiber brush filaments and polyurethane formulations, continuously refining its products for compatibility across diverse scenarios. The sales team has in-depth market knowledge and provides precise recommendations for deburring grinding heads and ceramic fiber brushes. The experienced after-sales team ensures swift response to guarantee production continuity and offers customized polishing solutions. Upholding the mission of providing efficient and high-quality solutions for the manufacturing industry, choosing LiChuang enables efficient, stable, and cost-effective metal processing. For inquiries: +86 134 3133 4931.