Innopower Glass polishing

Efficient, durable, and preciseProduct Introduction

Glass polishing solution is a polishing product specially developed for the characteristics and processing technology of glass materials, suitable for efficient grinding and polishing of ordinary glass, quartz glass, optical glass and other glass. This product uses cerium oxide as the core polishing component, with excellent suspension, easy cleaning, and stable polishing performance, which can significantly improve polishing efficiency and surface quality. It is an ideal choice for polishing and brightening various glass products, as well as removing scratches.

Product Features

Efficient polishing and precise grinding:

The scientific polishing formula brings excellent material removal rate and consistency, enabling high-precision surface treatment and significantly reducing processing time.

Good suspension and easy cleaning:

Cerium oxide particles are evenly distributed, with strong suspension stability and minimal residue after polishing, making cleaning convenient and time-saving.

Excellent stability:

The performance is stable and reliable, environmentally friendly, and produces no polluting gases. It is suitable for long-term continuous polishing operations and maintains consistent polishing effects.

Widely compatible and flexible in application:

Suitable for various polishing equipment and polishing pads, such as copper plates, tin plates, polyurethane pads, wool wheels, cloth wheels, etc., to meet various process requirements such as flat and curved surfaces.

Technical Specifications

| Coarse throwing liquid | Mid throwing liquid | Precision polishing solution |

|---|---|---|

| Used to remove thicker processing marks | Dealing with fine scratches remaining after rough polishing | Improve surface smoothness and glossiness |

Widely used

- Our polishing solution has a wide range of applications, suitable for polishing quartz glass, optical glass, and other glass products.

- Industry applications: This product is widely used in the following fields: precision machining industry, 3C electronics industry, automotive manufacturing and windshield processing, navigation and aviation glass components and other industries

Usage guide

- Flat product polishing: It is recommended to use a flat grinding and polishing machine to drip the shaken polishing solution onto the polishing surface (copper plate, iron plate, polyurethane pad, wool plate, etc.) at a rate of 5-10 ml/min. For large-scale production, automatic dripping can be achieved with magnetic stirring and peristaltic pumps.

- Polishing of curved and irregular products: Shake the liquid evenly before polishing and wet the hair wheel. It is recommended to use wool wheels during the rough throwing stage; For precision polishing, a cloth wheel can be used to achieve a finer and brighter effect.

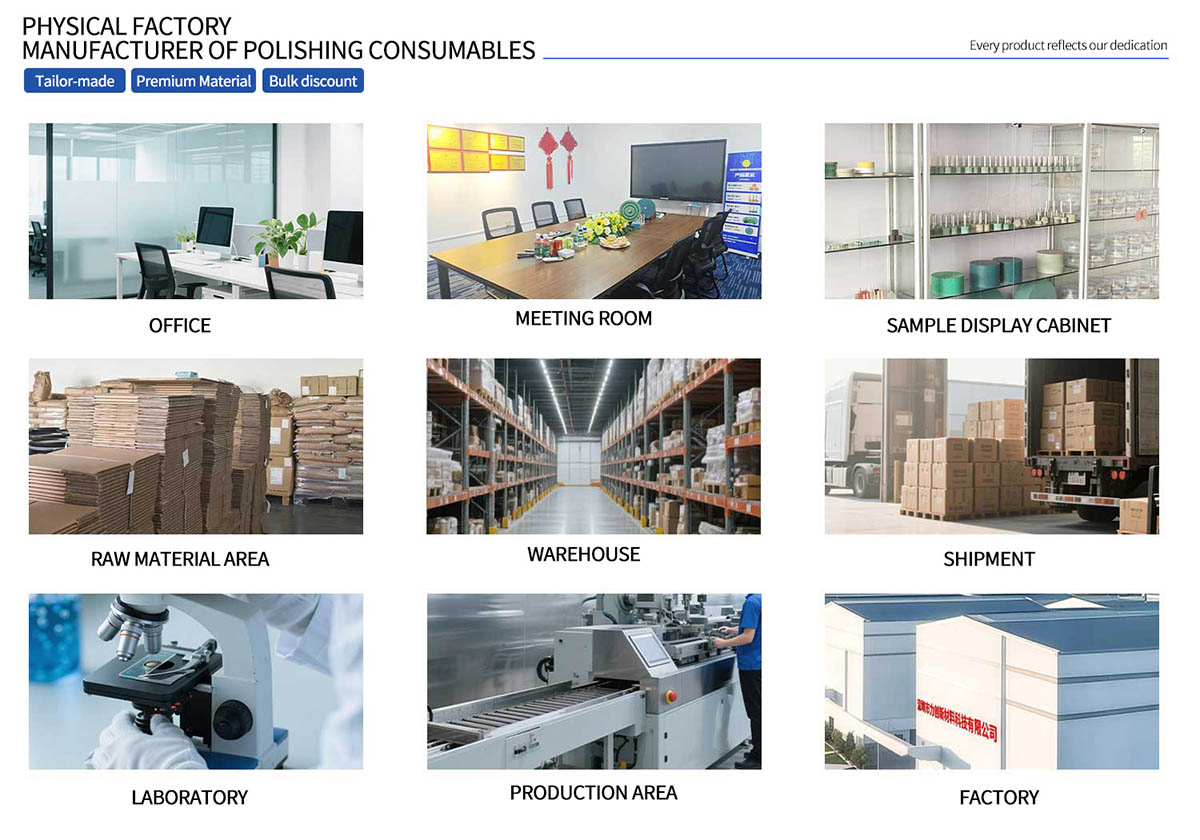

Why choose our polyurethane polishing head?

Shenzhen Innopower New Materials Technology Co.,Ltd. possesses robust R&D capabilities, with a team led by a director with over 20 years of experience in the abrasives industry. The company has independently mastered ceramic fiber brush filaments and polyurethane formulations, continuously refining its products for compatibility across diverse scenarios. The sales team has in-depth market knowledge and provides precise recommendations for deburring grinding heads and ceramic fiber brushes. The experienced after-sales team ensures swift response to guarantee production continuity and offers customized polishing solutions. Upholding the mission of providing efficient and high-quality solutions for the manufacturing industry, choosing LiChuang enables efficient, stable, and cost-effective metal processing.