Advantages and Applications of Liquid Polishing Wax

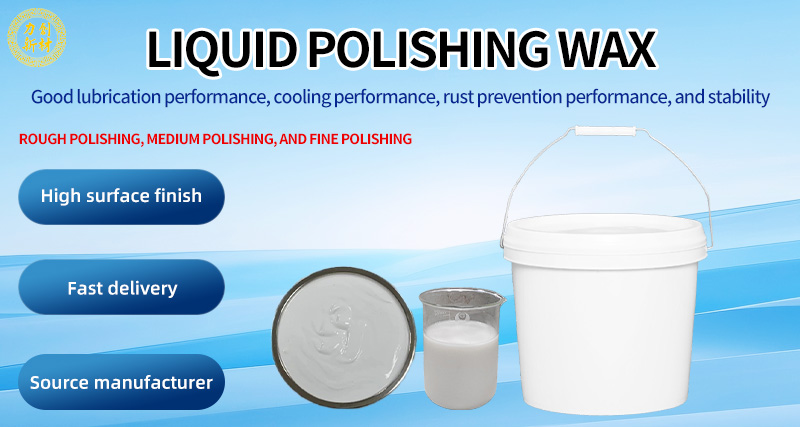

In modern manufacturing, surface treatment processes play a crucial role in enhancing product quality. Liquid polishing wax, also known as polishing slurry, is a polishing material made from aluminum oxide as the raw material through scientific formulation. It is primarily suitable for automated polishing processes, including rough, medium, and fine polishing of workpieces, helping to achieve efficient and precise surface treatment results.The advantages of liquid polishing wax are primarily reflected in multiple aspects. Firstly, it exhibits excellent lubricating properties, effectively reducing friction during the polishing process, minimizing equipment wear, and enhancing operational efficiency. Secondly, its cooling performance prevents workpieces from deformation or damage due to high temperatures, ensuring machining stability. Additionally, liquid polishing wax possesses anti-rust characteristics, protecting metal surfaces from corrosion and extending product lifespan. These combined properties significantly improve machining precision, achieving high surface finish and uniform texture on workpieces. Liquid polishing wax is also renowned for its rapid defoaming and environmentally friendly, pollution-free nature, aligning with modern industry's requirements for sustainable development and making it suitable for environmentally sensitive production environments.

Since its establishment, Shenzhen Innopower New Materials Technology Co.,Ltd. has consistently prioritized innovation and quality as the core of its corporate development. The company specializes in the research and development of polyurethane foam polishing wheels, with a team boasting 13 years of industry management experience. All members come from renowned large-scale abrasive and grinding tool enterprises, possessing high-quality professional manufacturing capabilities. By serving numerous precision machining companies, Lichuang has accumulated extensive practical experience, enabling it to provide specialized polishing consumable application solutions and address various challenges in surface treatment. Additionally, the company supports customized polishing consumables and services, helping clients optimize process efficiency. For further inquiries, please call the consultation hotline: +86-134-3133-4931.